Method and Technique

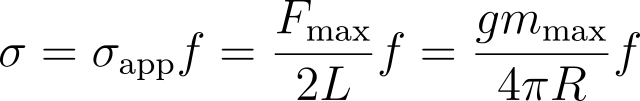

According to the ASTM D971 standard, the Du Noüy ring method can be used to measure the interfacial tension of oil against water. The interfacial tension is evaluated by measuring the maximum force (Fmax) a liquid lamella exerts on a wire ring while it is pulled out of a liquid. When the ring radius R is large compared to the radius r of the wire the interfacial tension σ can be calculated based on the following equation:

where L is the circumference of the ring, mmax is the maximum mass of the pulled lamella and g is Earth’s gravitational acceleration of approximately 9.81 m/s2.

The difference between the apparent and “actual” interfacial tension is corrected by the ring correction factor f. The tensiometer software DCATS offers correction factors according to various authors like Huh-Mason, Zuidema-Waters, or Harkins-Jordan.

A tensiometer of the DCAT series from DataPhysics Instruments is a universal measuring system for force-based studies of interfacial parameters and phenomena. With comprehensive software modules and standard test bodies, such as the Wilhelmy plate or the Du Noüy ring, it can determine the static, as well as time- and temperature-dependent IFT, thanks to its precise weighing system. Tensiometers are particularly useful for studying opaque liquids or liquids with similar refractive indices i.e., when the limits of optical contour analysis are reached.

Hence, a DCAT is the ideal device for measuring the interfacial tension of transformer oil against water according to ASTM D971, as will be shown in this note.